CS-71WO Butt Multi-Layers Welder for Pipe and Vessel

Home » Products » Rail Travelling Fillet » Rail Guide » CS-61WO/CS-71WO Butt Multi-Layers Welder for Pipe and Vessel

Rail Traveling Fillet Rail Guide

Rail Guide

CS-61WO / CS-71WO

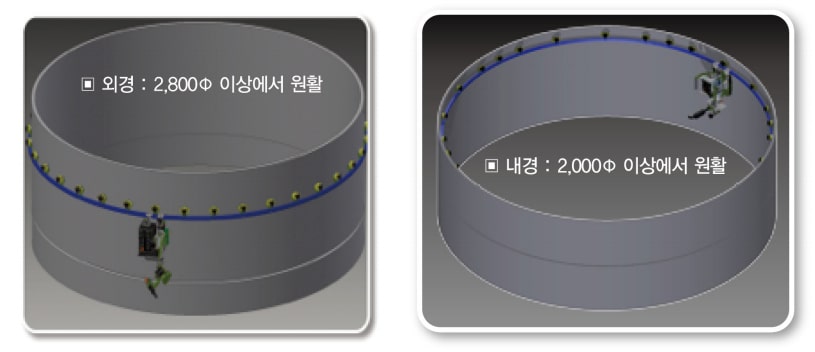

CS-71WO Butt Multi-Layers Welder for Pipe and Vessel is a high-performance device for multi-layer welding on circular pipes. It operates smoothly on pipes with an outer diameter of Ø2000 or more and has a reducer with no gear backlash, enhancing welding quality.

Download Catalog

Detail Info

- It is a butt multi-layers welder for the outer side of pipe and vessel, and the diameter should be more than 2000mm.

- The welder drives on the wheels with the guide rollers moving on the flexible rail, and it is controlled by the panel controller and the remote controller.

- The stop sensors of its both sides stop the welder automatically when a welding job is completed.

- Min. above 3 meter bending radius of the rail and easy to in-line by Magnet On-Off switch.

- It drives at a constant speed with the minimized gear backlash. Thus the high welding quality and the long life span of the welder is acquired.

- Controlling the weaving width, the desired leg length can be acquired in 1 time travelling.

- Using magnet release handle, it can be easily mounted and dismounted.

| DIVISION | CS-71WO | REMARK | ||

|---|---|---|---|---|

| General | AC Input Power | AC 100V~240V 50/60Hz | – | |

| DC Input Power(Option) | AC 48V | DC 18-72V(Option) | ||

| Dimensions | 391(W) X 379(L) X 283(H) | |||

| Weight | 8Kg | |||

| Body | Driving Method | 4 WHEELS DRIVEN | ||

| Traveling Speed | 0~98 cm/min | |||

| Traveling Motor | DC 24V, 12W, 5000RPM | BLDC MOTOR | ||

| Torch | Up / Down Angle | 0~60mm ±5% | ||

| Front / Back Distance | O~65mm ±5% | |||

| Running Angle | ±5%° | |||

| Weaver | Weaving Motor | DC 24V, 12W, 5000RPM | BLDC MOTOR | |

| Reducer | 1000 : 1 | |||

| Weaving Width | ± 16% | |||

| Weaving Speed | 0~5 rpm/min | |||

| Left / Right Stop time | 0.0~9.9(sec) | |||

| Center Shift | 0˚ ~ 360˚ | |||

| Distance for operating remocon | 10m | |||

| Welding Position | Fillet | Groove | PIPE |

| 1G, 2G | 2G |