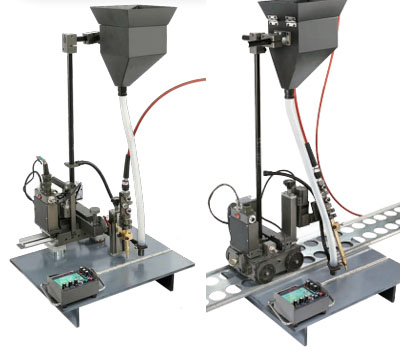

CS-SAW S.A.W Welder - Digital 4.3 Type

Rail Traveling Fillet Rail Mounted

Rail Mounted

CS-SAW S.A.W - Digital 4.3

CS-SAW S.A.W Welder – Digital 4.3 Type adopts a rail-running rack and pinion drive system. The compact and lightweight carriage is easy to move. It can weld thick base materials and adjust the weaving width according to thickness.

Download Catalog

Detail Info

• It is a rail traveling welder with the Rack & Pinion driving method.

• The welder is compact and lightweight, so it can be moved easily and conveniently.

• Productivity can be improved and welding cost can be reduced in flat position.

• A weaving device is installed so that even thick base materials can be welded, and the weaving

width can be adjusted according to the thickness.

• There is a left and right stop function to prevent insufficient penetration and undercut during

weaving welding

• It is possible to do precise control digitally such as running speed, weaving width, weaving speed,

left stop, right stop and etc.

• Using the lightweight rail with magswitch, the welder can be conveniently moved and easily installed.

| DIVISION | CS-SAW | |||

|---|---|---|---|---|

| General | AC Input Power | AC 100V~240V 50/60Hz | ||

| DC Input Power(Option) | AC 48V | DC 18-72V(Option) | ||

| Dimensions | 364(W) X 300(L) X542(H) | |||

| Weight | 18Kg (with rails) | |||

| Body | Driving Method | Rack Pinion Driven | ||

| Traveling Speed | 0~88 cm/min | |||

| Traveling Motor | DC 24V, 12W, 5000RPM BLDC MOTOR | |||

| Y Slide | Stroke | 100mm ±5% | ||

| Z Slide | Stroke | 145mm ±5% | ||

| Weaver | Motor | DC 24V, 12W, 5000RPM BLDC MOTOR | ||

| Weaving Width | 0˚~360˚ | |||

| Weaving Speed | 0~5 rpm/min | |||

| Left / Right Stop | 0.0~9.9(sec) | |||

| Center Shift | 0˚ ~ 360˚ | |||

| Rail | Fixing | Magnet ON/OFF type | ||

| Material / Size | AL / 1.5M / 9.4Kg | |||

|

Rail(option) |

Fixing | Cutting Track | ||

| Material / Size | AL / 1.8M (1816*215) | |||

| Welding Position | Fillet | Groove | PIPE |

| 1G |

Go to product details