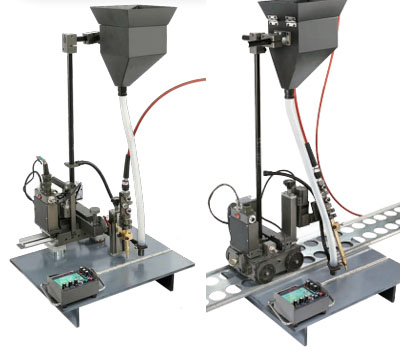

Rail Mounted

It attaches directly to the rail and moves with it, so it's simple to install, relatively inexpensive, and compatible with many different types of rails.

Rail Guide

The guides inside the rails provide high precision and repeatability, with low friction for long life and low noise.

Rail Pipe

You can customize rails for the pipe to increase productivity when welding the inner diameter/outer diameter of the pipe.

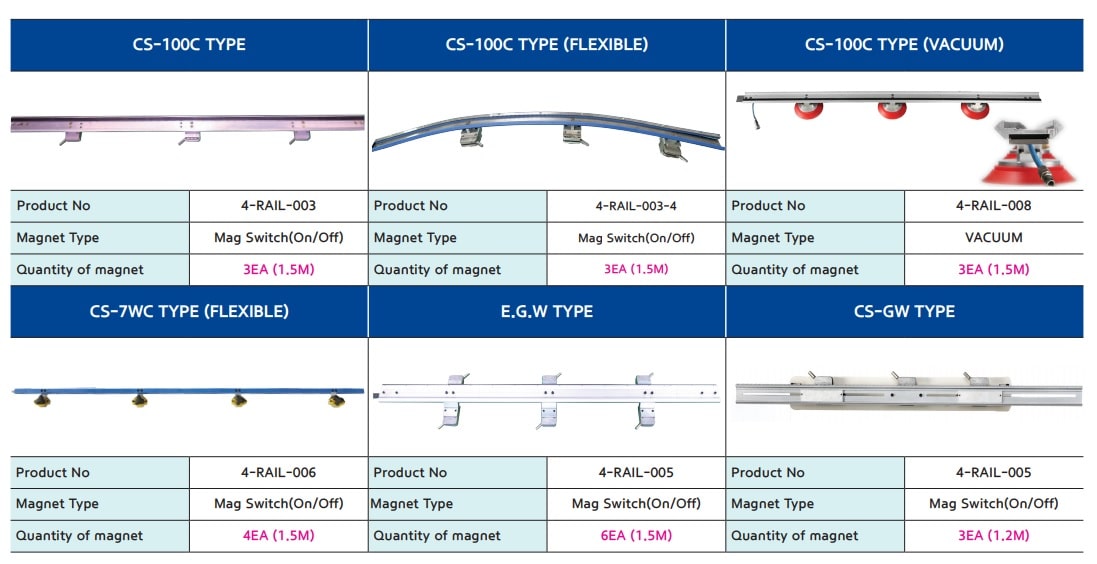

Rail List

You can see the different types of Mag Switch (On/Off), Pressure Clamp rails.